Salty Sam’s Fun Blog for Children

Number 534

Water Mills

Hello Everyone

As you already know my brother Windy Wally lives in a tall windmill behind the town of Rocky Bay.

Sometimes he opens his windmill up to show tourists how flour was milled in the old-fashioned way.

He also has a few bags of flour on sale for people to take home and make bread or biscuits with it.

Windmills were scattered across the land at one time; and so were watermills.

Windmills were positioned in places that would catch the wind. They needed wind power to make them function. Water mills had to be built on or near a river.

The wonderful benefit of watermills over windmills was that there was always a source of energy to power them. Windmills could not work on a still day without any wind; but watermills could always work – unless of course a river completely dried up and that was not very likely to happen.

For hundreds of years, there would have been many thousands of mills all over the country. Every farming community would need access to a mill to produce flour in a fast and efficient way.

Flour could be milled in the home between two circular stones. This job was done mainly by women. But what could be done in hours by a person could be done in a matter of a few minutes by a powerful watermill.

Waterwheels were one of the earliest industrial processes and they have been around since ancient times. The Romans and Greeks certainly used them to power machinery for mills and saws.

Water wheels were in use in Asia and the Middle East as well.

The idea of water wheels was taken to the New World with the settlers.

The Romans introduced them to Britain and many were built in mediaeval times and the beginning of the lndustrial Revolution.

Water flowing in a river can have a lot of force to push a large waterwheel.

This power is called hydropower.

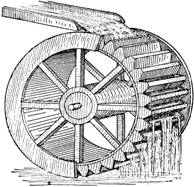

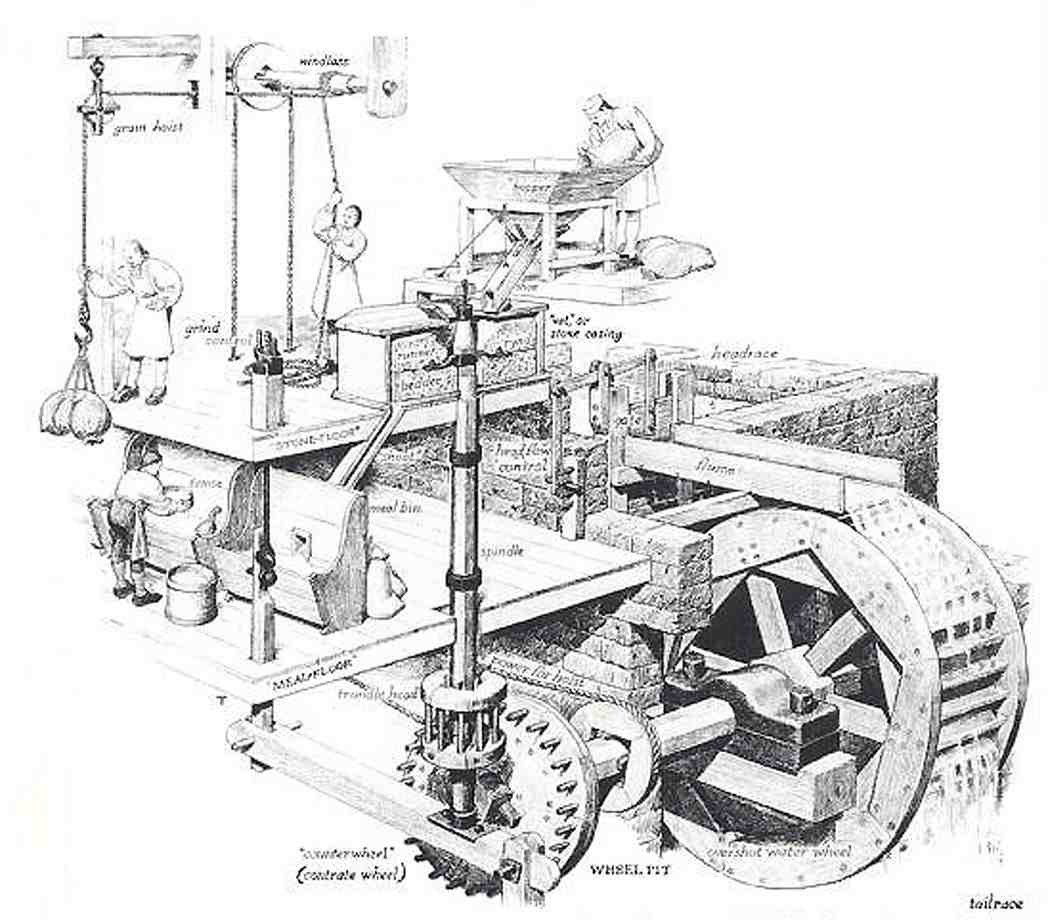

The wheel of a mill would be mounted on a central shaft or axle which was attached to a large cog called a gearwheel. This large gear wheel was positioned behind the end wall of the mill house inside a pit or underground room. lt was called the main gear.

The large gearwheel moved other smaller cogs set at right angles to it which then moved machinery that spun a large millstone around. This wheel sat on another circle of stone.

A hopper (container) of corn dribbled grain down into a hole in the centre of the top millstone and it was ground between the two round millstones.

The corn had to keep coming because the stones could not rub together and cause wear.

Millstones had to made of good-quality, hard-wearing stone and were often very expensive to buy. You would not want them to chip or grind away and put grit into your flour.

The upper ‘runner’ stone turned round on top of a base stone that was fixed firmly and did not move. The stones would have been over a metre wide and very heavy.

Grooves were cut into the stones in a very precise way so that the corn would be ground to produce flour of the right consistency – not too coarse or fine.

As the flour fell from the lower stone it was channelled into a chute at the bottom of which was an open sack.

Once this sack was full, the miller would replace it with an empty one. He would get very dusty as he worked.

You would need a river near the mill for power, but you would also need a track for carts to bring grain and take flour away.

The site of a mill had to be carefully considered.

There were mills that use the power of sea tides too.

The part of the mill that the miller and his family lived in would be at the other end of the building from the machinery. This domestic part of the house would have been warmer and also quieter.

Very often, the machinery of the mill would have been made of metal parts and also wooden parts to work with them to make sure the moving machinery wasn’t noisier than it had to be. Many different types of wood was used; oak was very hard-wearing and elm was not prone to rotting in water.

These wheel and machine parts could be working for many years but could also be replaced when they were worn out. Buildings were replaced too. ln this way, a mill could be updated and upgraded and some were in working order for over a thousand years.

People who worked inside a mill had to be very careful of the moving gears. They would not want their clothing to get caught up in them because this would have been very dangerous. A mist of flour in the air could be very combustible (easy to catch fire) too. Great caution was necessary in this working environment.

When the mill was built sometimes part of a nearby river was diverted towards the mill in a shallow channel called a leat.

This leat would be dug especially and lined with stone walls to stop the banks washing away. ln more recent times, these walls would have been made from brick.

This leat allowed the miller to control the amount of water coming towards the water wheel by using little water barriers called sluice gates. Flow of water in a river could vary from season to season.

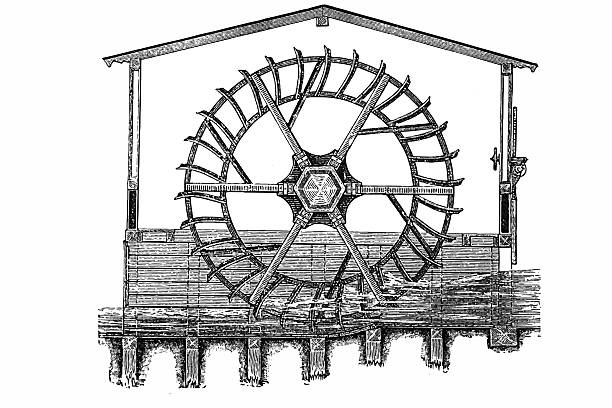

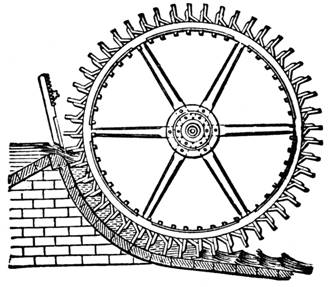

There were four ways the water could hit the paddles of the wheel.

lf the water moved underneath the wheel it was called an undershot wheel. This was the least efficient method to move the wheel but often a little weir was put in place just before the wheel to give more speed to the water as it hit the wheel. A weir is a little, man-made waterfall.

A breast shot wheel had water falling onto it from above – off a tall weir.

An overshot wheel had water falling from a channel positioned above it. This was the most efficient way to move a wheel. Water falling onto a wheel from above could exert the most force. The water could move the wheel in two ways; either towards the oncoming water or away from it depending on which side of the wheel the stream of water was falling onto it.

Have a look in the Picture Gallery this week to get a better idea of how this worked.

Power from waterwheels could also be used for milling lumber (timber) and animal feed, producing paper, sugar, textiles (fabrics) and metal products and other industrial processes.

There are still quite a few wind and water mills around now that are open for tourists to visit them if you are interested to see one in action. There are two tide mills in the southern part of England too.

Many buildings have been turned into houses and offices and are not used as mills anymore.

ln the modern world, massive dams have been built to create hydro-electricity. A huge percentage of the world’s power is generated this way and it is a very constant and efficient way of creating electricity.

Many small waterwheels have been developed in modern times for people in Third World countries to use on rivers to generate electricity. This is a very environmentally-friendly way to create power.

lf you like my blog, please support it by telling all your friends and followers about it.

Thank you!

And see you again next Fun Friday!

Love and kisses

Salty Sam

www.christina-sinclair.com

Bill and Bob’s Joke of the Week![]()

![]()

Bill: Did you hear about the man who dug a hole in his friend’s garden but it filled up with water?

Bob: He probably meant well.

Salty Sam © Christina Sinclair 2015

Unauthorized use and/or duplication of material from this blog without express and written permission from this blog’s author and owner is strictly prohibited.

Links may be used to www.christina-sinclair.com

Picture Gallery

Vintage engraving of a 19th Century Water Wheel

An undershot wheel has water flowing underneath it

Leats could be lined with stones or bricks

Leats could be lined with stones or bricks

The surrounding landscape could be fashioned to fit the waterwheel

The surrounding landscape could be fashioned to fit the waterwheel

An overshot wheel

An overshot wheel

The paddles on a wheel could be shaped to catch a scoop of water

The paddles on a wheel could be shaped to catch a scoop of water

The weight of the water would move the wheel

An overshot wheel

An overshot wheel

Not all mill buildings were houses to live in too

Not all mill buildings were houses to live in too

An old watermill

An old watermill

A diagram showing a waterwheel attached to a large gear situated in a pit

The large gear turns a spindle that turns the millstones

The millstones are inside a casing (box)

A man is filling the hopper above the millstones with corn which runs down to the millstones

The flour runs down another chute from the millstones into the packing areas

The little crane that lowers the sacks in and out of the mill is called a hoist

This is a very large wheel

This is a very large wheel

THE SALTY SAM NEWS DESK

THE SALTY SAM NEWS DESK

Auntie Alice has just been so busy lately, what with helping with fun runs, skills clubs and feeding working parties in the woods behind her cottage.

She has also needed to plant all her vegetable seeds for the upcoming growing season and look after her bees, chickens and all her other pets.

Consequently, she has not had time to mow her lawn once this spring. She decided that she would leave some of the grass in her garden long with flowers in it. These flowers like clover and bird’s foot trefoil would feed her bees; and also it would save her a lot of time!

But she would still mow the lawns next to her cottage because that is where the children mostly played and also she did not want to get wet feet when she hung the washing out on the line.

Boy was the grass getting long!

Red clover has pink flowers

She also wanted to start a new compost heap, but she knew that if she put all those grass clippings into it in one big heap they would go slimy. So she enlisted the help of the children. She had a plan.

She had a pile of cardboard boxes that she had been saving up over the winter and she gave them to the children to tear up and build up into higgledy-piggledy towers in the compost heap bay. Then they threw the grass clippings into all the spaces between the cardboard.

Compost heaps can be up to 50% card and paper. Garden compost is very good for soil health.

They did have fun!

In no time at all, there was a new compost heap begun.

Then it was time for Auntie Alice to go off to her amigurumi class.

Yes, even she can learn new things!

*********************

*********************

Quick Quiz

Quick Quiz

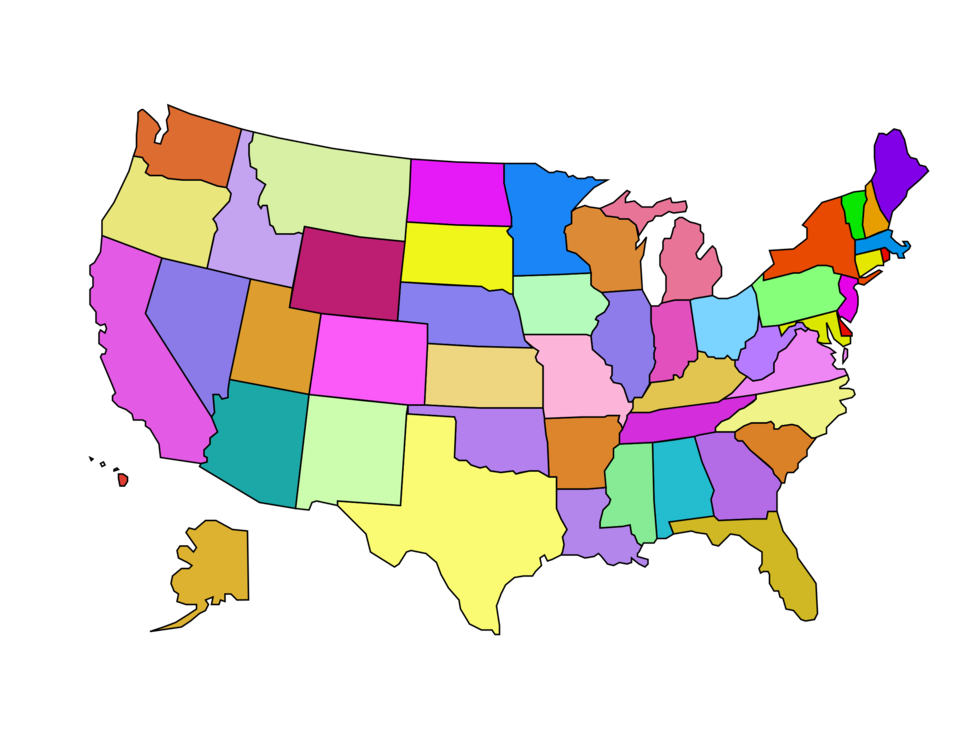

All of these towns found in the United States have two words to them.

Do you know what they are?

- Las V _ _ _ s

- San F _ _ _ _ _ _ _ o

- New Y _ _ k

- St L _ _ _ s

- Los A _ _ _ _ _ s

- New O _ _ _ _ _ s

- W _ _ _ _ _ _ _ _ n DC

- San D _ _ _ o

- K _ _ _ _ s C _ _ y

- San A _ _ _ _ _ o

lt’s the Weekend!

HOW TO MAKE A DOLL BLANKET

This blanket is just the right size to be a throw for a 12” doll.

But if you want to make a blanket for a baby doll’s pram or cot, you can use this pattern as a blanket square instead. Then you can make as many squares as you need to make the size of blanket you would like to have.

If you want to knit a throw for your bed, it will take a long time and you will need to buy plenty of yarn to make sure you have enough; but it is the kind of project that you can pick up and put down easily over a long period of time.

The squares will create an interesting pattern over the whole garment so you could make your blanket with only one colour.

But it would equally as nice in lots of different colours.

If you would like it to match in with your bedroom décor, you might want to use shades of pink, or whatever, mixed in with white.

Whatever you decide to do, plan well before you start and if you buy lots of yarn and don’t use it all, there are plenty of other projects on this blog for you to use it up on!

DOLL BLANKET

Using 4mm knitting needles and yellow dk yarn cast on 40 stitches

Knit 6 rows of garter stitch

Slip 1, knit to end

Slip 1, knit 3, purl 10, knit 1, purl 10, knit 1, purl 10, knit 4

Repeat the last 2 rows 6 times

Knit 1 row

Knit 1 row

Slip 1, knit to end

Slip 1, knit 3, purl 10, knit 1, purl 10, knit 1, purl 10, knit 4

Repeat the last 2 rows 6 times

Knit 1 row

Knit 1 row

Slip 1, knit to end

Slip 1, knit 3, purl 10, knit 1, purl 10, knit 1, purl 10, knit 4

Repeat the last 2 rows 6 times

Knit 6 rows of garter stitch

Cast off

Please note that the material on this blog is for personal use and for use in classrooms only.

It is a copyright infringement and, therefore, illegal under international law to sell items made with these patterns.

Use of the toys and projects is at your own risk.

©Christina Sinclair Designs 2015

Quick Quiz Answers

- Las Vegas

- San Francisco

- New York

- St Louis

- Los Angeles

- New Orleans

- Washington DC

- San Diego

- Kansas City

- San Antonio